Porducts

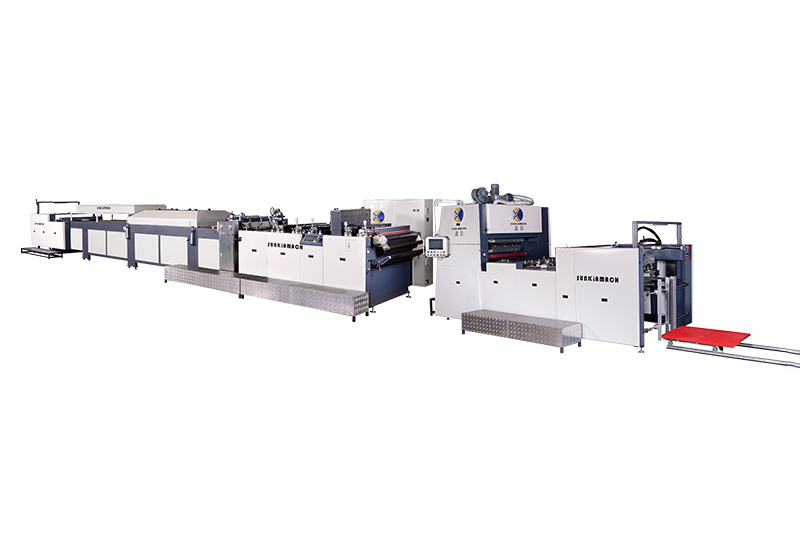

High Speed and Intelligent Laminating Machine + Primer Coating on Line Machine

Configuration

Paper Feeder

Adopt servo shaftless drive, High-speed feeder heads with four-suction, four-feec structure, available for both thin and thicDADe.

High Precision Servo-Drive Will Control the Paper Overlap System

Dust Remover

Electrostatic powder cleaner can remove more than 90% of dust from paper surface.

Gluing System for Window Lamination Products

It is available for both water-based glue and oily glue, also the glue can be averagely coated.

IR Drying System

Two options: Half-power heating OR full-power heating.

Coating System

Ceramic roller work with blade system to control the glue thickness and glue consumption.

Eletromagnetic Heating System

Low heat loss, high utilization, fast heating, 20% energy saving.

Flying-Knife Cutter

Flying-knife cutter specialized in thin paper, PET, PVC, thin film, it is available for all kinds of film.

Snapping System

Snapping roller system suitable for different sizes of the sheet, and it is more stable for thin paper cutting with easy adjustment.

Paper Delivery System

Pneumatic jogging system, waste discharge system, paper can be neatly collected even under high speed production.

Human Machine Interface

Humanized design, rotatable operation.

Electric Box in CE Standard

Imported electrical components, PLC control system for circuit.

Specification

| Model | XJFMV-1200 | XJFMV1200L | XJFMV-1200XL |

| Speed(M/min) | 25-80 | 25-80 | 25-70 |

| Paper Thickness(g/m2) | 100-500 | 100-500 | 100-500 |

| Max. Sheet Size(W*L)mm | 1200*1200 | 1200*1450 | 1200*1650 |

| Min. Sheet Size(W*L)mm | 300*300 | 300*300 | 350*350 |

| Power Requirement(KW) | 92 | 96 | 96 |

| Production Power(KW) | 48 | 58 | 66 |

| Dimension(L*W*H)mm | 21380*3820*2800 | 21780*3820*2800 | 22180*3820*2800 |

Advantage

Global pioneer, Firstly, using standard OPP or PET film, after laminating with paper and cutting system, and then go to coating system , coating at paper surface layer of anti-scratch UV oil, soft touch oil, and primer oil etc, then go through ultraviolet or infrared drying, the coated paper can become high-end scratch-resistant film, soft touch film and UV printing with metalized silver or gold cardboard, reduce the cost of the production materials, and then to screen printing UV next procedure and hot stamping, paper surface adhesion effect will be better.

Range Of Application

High-end gift boxes, cosmetics boxes, mobile phone boxes, handbags, high-precision electronic products and expensive electrical products and other surface laminating process.