Porducts

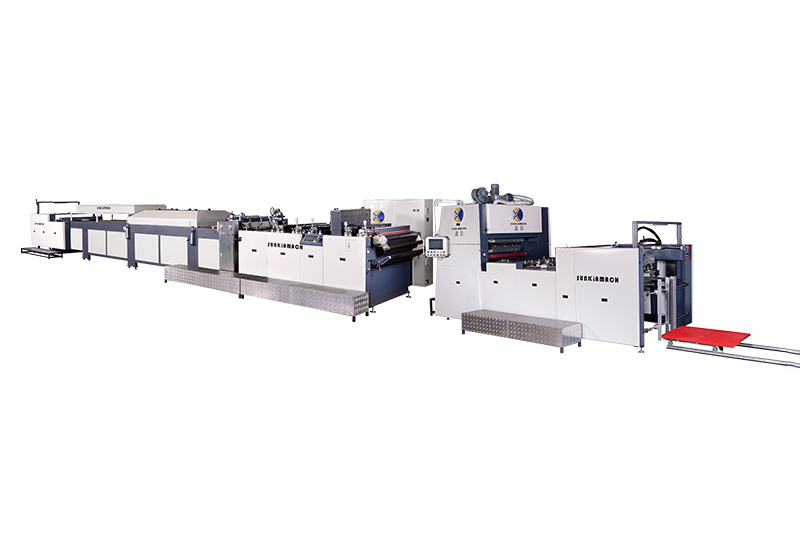

Automatic Multifunction Coating · Window Laminating Machineoil Instead of Plastic/ Water Based Varnishing/ Blister Oil

Configuration

Paper Feeder

Adopt servo shaftless drive, High-speed feeder heads with four-suction, four-feec structure, available for both thin and thicDADe.

High Precision Servo-Drive Will Control the Paper Overlap System

Dust Remover

The electrostatic precipitator can remove more than 90% of the dust on the paper surface.

Gluing System for Window Lamination Products

It is compatible with water-based and oil-based glues, ensuring even glue application.

IR Drying System

Two options: Half-power heating OR full-power heating.

Coating System

The ceramic roller works in conjunction with the blade system to regulate the thickness of the glue and minimize glue consumption.

Eletromagnetic Heating System

Minimal heat loss, high efficiency, rapid heating, and 20% energy saving.

Flying-Knife Cutter

The flying knife cutting machine is specially designed for tissue paper, PET, PVC, and film, and is compatible with many types of films.

Snapping System

The nip roller system accommodates different paper sizes and provides enhanced stability for cutting thin paper and is easy to adjust.

Paper Delivery System

The pneumatic inching system and waste removal system ensure neat collection of sheets even during high-speed production.

Human Machine Interface

Humanized design, rotatable operation.

Electric Box in CE Standard

Imported electrical components, PLC control system for circuit.

Specification

| Model | XJFMKC-1200 | XJFMKC-1200L | XJFMKC-1200XL |

| Speed(M/min) | 25-80 | 25-80 | 25-70 |

| Paper Thickness(g/m2) | 100-500 | 100-500 | 100-500 |

| Max. Sheet Size(W*L)mm | 1200*1200 | 1200*1450 | 1200*1650 |

| Min. Sheet Size(W*L)mm | 300*300 | 300*300 | 350*350 |

| Power Requirement(KW) | 60 | 65 | 70 |

| Production Power(KW) | 30 | 35 | 45 |

| Dimension(L*W*H)mm | 13500*2600*2800 | 14500*2600*2800 | 16500*4300*2800 |

| Machine Weight(KG) | 11300 | 12000 | 16000 |