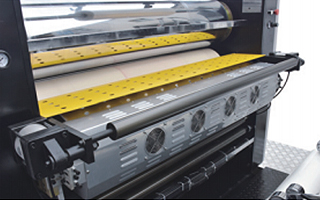

OEM/ODM Factory Lamination Cutter Machine - Automatic Thermal Film Lamination Machine(single or double side laminated, being optional) – Sunkia Detail:

Configuration

Auto Feeder

This macine is equipped with a paper pre-stacker. Servo controlled feeder and a photoelectric sensor to ensure that paper is continuously fed into the machine

The servo controller and side lay

mechanism guarantees precise

paper alignment at all times.

Equipped with advanced

electromagnetic heater.

Fast pre-heating

Energy-saving

Environment protection

Human-computer interface An user-friendly interface system with a colour touchscreen simplifies the operation process. The operator can easily and automatically control paper sizes, overlapping and machine speed.

Perforating and cutting knife

Chain cutter system applying bopp, pet, pvc film and etc, Having the feature of accurate separation without film margin

Corrugated Delivery A corrugated delivery system collects paper easily

Automatic Stacker receive the sheets

quickly in order without stopping the

machine as well as counter the sheets

Specification

|

Model |

XJFMA-1050 |

XJFMA-1050L |

|

Max paper size |

1050*1100mm |

1050*1200mm |

|

Min paper size |

340*340mm |

450*450mm |

|

Paper weight |

100-500g/m2 |

105-500g/m2 |

|

Laminating speed |

0-80m/min |

0-80m/min |

|

Power |

35kw |

37kw |

|

Total Weight |

7000kg |

7600kg |

|

Overall Dimensions |

9000*2200*1900mm |

10600*2400*1900mm |

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for OEM/ODM Factory Lamination Cutter Machine - Automatic Thermal Film Lamination Machine(single or double side laminated, being optional) – Sunkia, The product will supply to all over the world, such as: Cannes, Rwanda, Indonesia, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

-

Hot Sale for Thermal Roll Lamination Machine -...

-

Cheapest Price Milk Packing Machine - Manual c...

-

factory customized Uv Varnish Coating Machine -...

-

Super Lowest Price Sheet Lamination Machine - ...

-

Massive Selection for Uv Cure Conformal Coating...

-

18 Years Factory Full Uv Coating Machines - Au...