OEM Factory for Lamination Press Machine - Automatic High-Speed Multifunctional Window Lamination Machine (Water-based Glue/Oily Glue/Pre-coated Film) – Sunkia Detail:

Characteristics

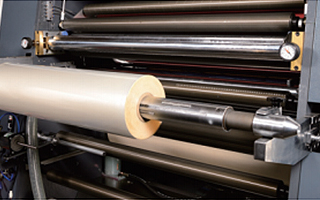

♦ This is a multifunctional window laminating machine, by heating and pressing the laminating steel roller to laminate the film on the glued paper. Good lamination effect can be reached and the cost is reduced.

♦ Thermal energy utilization reaches 95%, and the heating rate is doubled.

♦ Servo drive system controls the paper overlap system, making paper overlap more stable, effcient and accurate.

♦ Heat recycling system, effectively reduce heat loss, more energy saving and environmental protection, improve efficiency by 25%.

♦ Flying-knife laminating machine: Flying-knife cutter system is specialized in thin paper, PET, PVC, thin film, it is available for all kinds of film.

Configuration

Paper Feeder

High-speed feeder heads with four-suction, four-feed is applying into kinds of thin and thick paper.

High precision servo-drive will

control the paper overlap system

Dust Remover

Electrostatic powder cleaner can remove more than 90% of dust from paper surface.

Gluing system for window lamination products

It is available for both water-based glue and oily glue, also the glue can be averagely coated.

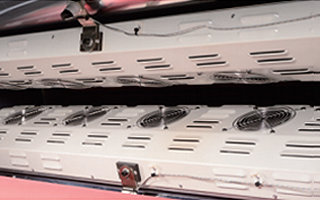

IR drying system

Two options: Half-power heating OR full-power heating

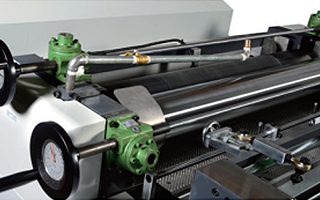

Coating System

Ceramic roller work with blade system to control the glue thickness and glue consumption.

Eletromagnetic heating system

Low heat loss, high utilization,

fast heating,

20% energy saving

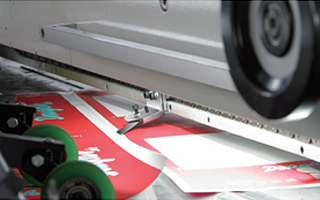

Flying-Knife Cutter

Flying-knife cutter specialized in thin paper, PET, PVC, thin film, it is available for all kinds of film.

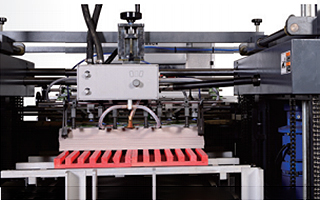

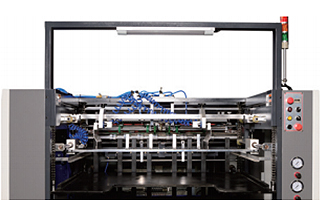

Snapping System

Snapping roller system suitable for different sizes of the sheet, and it is more stable for thin paper cutting with easy adjustment.

Paper delivery system

Pneumatic jogging system, waste discharge system, paper can be neatly collected even under high speed production

Human Machine Interface

Humanized design,

rotatable operation

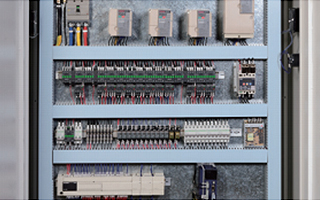

Electric box in CE standard

Imported electrical components, PLC control system for circuit

Specification

|

Model |

XJFMKC-1200 |

XJFMKC-1200L |

XJFMKC-1200XL |

|

Speed(M/min) |

25-80 |

25-80 |

25-70 |

|

Paper Thickness(g/m2) |

100-500 |

100-500 |

100-500 |

|

Max. Sheet Size(W*L)mm |

1200*1200 |

1200*1450 |

1200*1650 |

|

Min. Sheet Size(W*L)mm |

300*300 |

300*300 |

350*350 |

|

Power Requirement(KW) |

60 |

65 |

70 |

|

Production Power(KW) |

30 |

35 |

45 |

|

Dimension(L*W*H)mm |

13500*2600*2800 |

14500*2600*2800 |

16500*4300*2800 |

|

Machine Weight(KG) |

11300 |

12000 |

16000 |

Product detail pictures:

Related Product Guide:

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for OEM Factory for Lamination Press Machine - Automatic High-Speed Multifunctional Window Lamination Machine (Water-based Glue/Oily Glue/Pre-coated Film) – Sunkia, The product will supply to all over the world, such as: luzern, Costa rica, Orlando, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.