Factory wholesale Uv Resistant Epoxy - Automatic High Speed UV Spot Varnishing Machine(Dual Functions, for both thick and thin paper)Half-way Grip Tooth Conveying – Sunkia Detail:

| STANDARD EQUIPMENTS | OPTIONAL EQUIPMENTS |

| Auto Feeder | Non-stop Feeding and Delivery Mechanism |

| Multifunctional Coating Unit | Pre-stack Car Device |

| UV Drying System | Ceramic Anilox Roller |

| Auto Delivery Unit | |

| Auto Control |

Configuration

Feeder

Enlarged feeder with four sucking and six sending, and the spool adds a blower channel to send paper smoothly and easily.

Front Side Lay Gauge

When sheet reaches front lay gauge, left and right pulling lay gauge can be chosen. The machine can stop feeding immediately by sensor once sheet missed or run out, meanwhile pressure released to keep bottom roller under no varnish condition.

Varnish Supply

Steel roller and rubber roller with metering roller reversing and scraper structure control varnish consumption and volume to meet the demand of products and operate easily. (Varnish consumption and volume are determined by the line qty of ceramic anilox roller)

Transferring Unit

After sheet is transferred from pressure cylinder to gripper, paper can be supported by air blowing and smoothly reversed which can prevent sheet surface from being scratched.

Sheet Delivery

Pneumatic control through the electric eye count automatic paper align, automatic drop, so that the delivery is very smooth. The rear gear is electronically controlled, allowing samples to be easily, quickly and safely taken out during product inspection.

Conveying Unit

Upper and lower conveying belt can form

thin sheet to be curved for neat

and smooth delivery.

Sheet Putting

Sheet putting is achieved by cam and air blowing together to guarantee sheet is smoothly put on the conveying belt.

Auto Lubrication

The bearing sleeve uses automatic lubricating oil, the lubrication time can be adjusted and controlled so that to achieve the best lubrication.

Specification

|

Model |

XJU-1040 |

XJU-1280 |

XJU-1450 |

XJU-1620 |

|

Max. Sheet Size |

730*1040mm |

920*1280mm |

1100*1450mm |

1300*1620mm |

|

Min. Sheet Size |

310*406mm |

310*406mm |

350*460mm |

500*460mm |

|

Max. Coating Area |

720*1030mm |

910*1270mm |

1090*1440mm |

1290*1610mm |

|

Sheet Thickness |

80~500gsm |

80~600gsm |

80~600gsm |

125~500gsm |

|

Coating Accuracy |

±02.mm |

±0.2mm |

±0.2mm |

±0.2mm |

|

Production Speed |

7200sheets/hour |

5200sheets/hour |

5000sheets/hour |

3000sheets/hour |

|

Total Power |

42.8kw(oily)/44kw(water-based) |

51.5kw(oily) |

52kw(oily) |

53kw(oily) |

|

Dimension(L*W*H) |

12800*3400*2300mm |

12800*3600*2360mm |

12800*3600*2300mm |

12840*3400*2360mm |

|

Machine Weight |

8000kg |

9300kg |

10800kg |

12000kg |

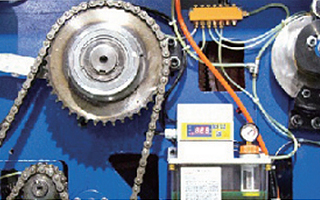

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Factory wholesale Uv Resistant Epoxy - Automatic High Speed UV Spot Varnishing Machine(Dual Functions, for both thick and thin paper)Half-way Grip Tooth Conveying – Sunkia, The product will supply to all over the world, such as: Sydney, Portland, Denmark, We welcome you to visit our company and factory. It is also convenient to visit our website. Our sales team will offer you the best service. If you need more information, please feel free to contact us by E-mail or telephone. We are sincerely hope to establish a good long-term business relationship with you through this opportunity, based on equal, mutual benefit from now till the future.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

-

Manufacturing Companies for Kraft Paper Laminat...

-

OEM/ODM Manufacturer Gift Box Making Machine -...

-

High Quality Coating Uv - Automatic High Speed...

-

China wholesale Uv Roller Coater - Automatic H...

-

Factory source Rigid Box Maker - Fully automat...

-

Wholesale Price Industrial Laminating Machine -...