Factory wholesale Matt Lamination Machine - Automatic Thermal Film Lamination Machine(single or double side laminated, being optional) – Sunkia Detail:

Configuration

Auto Feeder

This macine is equipped with a paper pre-stacker. Servo controlled feeder and a photoelectric sensor to ensure that paper is continuously fed into the machine

The servo controller and side lay

mechanism guarantees precise

paper alignment at all times.

Equipped with advanced

electromagnetic heater.

Fast pre-heating

Energy-saving

Environment protection

Human-computer interface An user-friendly interface system with a colour touchscreen simplifies the operation process. The operator can easily and automatically control paper sizes, overlapping and machine speed.

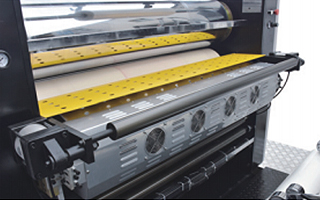

Perforating and cutting knife

Chain cutter system applying bopp, pet, pvc film and etc, Having the feature of accurate separation without film margin

Corrugated Delivery A corrugated delivery system collects paper easily

Automatic Stacker receive the sheets

quickly in order without stopping the

machine as well as counter the sheets

Specification

|

Model |

XJFMA-1050 |

XJFMA-1050L |

|

Max paper size |

1050*1100mm |

1050*1200mm |

|

Min paper size |

340*340mm |

450*450mm |

|

Paper weight |

100-500g/m2 |

105-500g/m2 |

|

Laminating speed |

0-80m/min |

0-80m/min |

|

Power |

35kw |

37kw |

|

Total Weight |

7000kg |

7600kg |

|

Overall Dimensions |

9000*2200*1900mm |

10600*2400*1900mm |

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Factory wholesale Matt Lamination Machine - Automatic Thermal Film Lamination Machine(single or double side laminated, being optional) – Sunkia, The product will supply to all over the world, such as: France, Netherlands, Libya, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!

-

Hot Sale for Masala Packing Machine - Pressure...

-

OEM Customized Lamination Paper Cutting Machine...

-

Factory Cheap Hot Automatic Window Type Laminat...

-

Rapid Delivery for Uv Varnish Coating - Automa...

-

New Delivery for Matte Uv Coating - Automatic ...

-

Reliable Supplier Uv Coating For Marble - Auto...